What Initiating Event Frequency Do I Use?

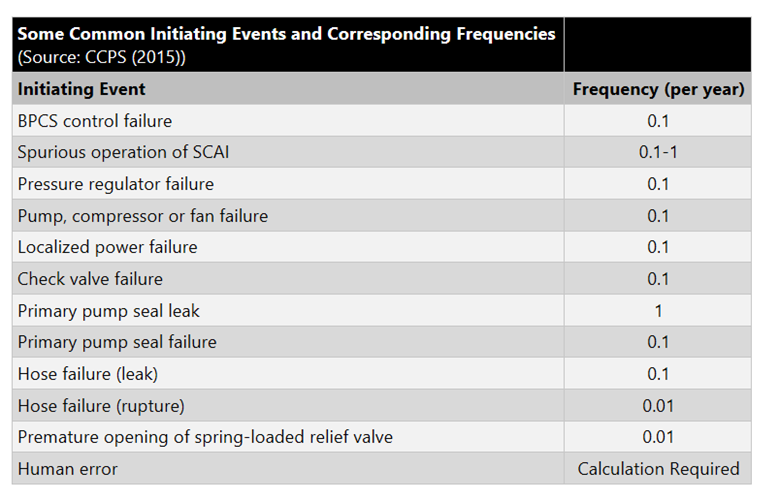

When determining the frequency of initiating events in a LOPA, there are a number of different factors to consider. The table below summarizes some common initiating events and suggested guidelines for corresponding frequencies as per CCPS’s Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection Analysis (2015). It should be noted that these frequencies are considered guidelines, and they may not always be applicable to a given project depending on the operating conditions being analyzed. This underscores the importance of having detailed conversations with your team when discussing each individual cause during a PHA.

Instrumented system initiating events

Basic Process Control System (BPCS) control failure – 0.1 chance per year

Dangerous failure rate of BPCS (assuming that it does not conform to IEC 61511) is assumed to be at least 1 x 10e-5 per hour, which is approximately 0.1 chance per year

BPCS controls are also susceptible to human error (e.g. operators changing set points)

Safety Control Alarm and Interlock (SCAI) spurious operation – 0.1 chance per year to once per year

A safety control alarm or interlock exhibiting safe failures (e.g. partially activates even when process conditions do not warrant its activation)

Often referred to as a “nuisance trip”

Active mechanical component initiating events

There are a number of different active mechanical components which may fail and initiate a sequence of events leading to a consequence.

Pressure regulator fails to operate as designated – 0.1 chance per year

Assumed to be operating in a continuous mode

Pump, compressor, fan or blower failure – 0.1 chance per year

Site-wide power loss – no initiating event frequency guideline

Some sites have frequent power failures (e.g. due to weather events)

Some sites rarely lose power

Localized power loss – 0.1 chance per year

Considered as a single circuit loss of power

Check valve failure – 0.01 to 0.1 chance per year

Single check – 0.1 chance per year (assuming clean vapour, steam or other non-plugging service)

Double checks in series – 0.01 chance per year (assuming adequate maintenance program in place)

Loss of containment initiating events

The following loss of containment events are considered to happen relatively frequently:

Primary pump seal leak – once per year

Primary pump seal failure – 0.1 chance per year

Hose failure (leak) – 0.1 chance per year

Hose failure (rupture) – 0.01 chance per year

Premature opening of spring-loaded relief valve – 0.01 chance per year

The following loss of containment events are considered quite remote and are not typically considered in the analysis (unless otherwise specified):

Atmospheric tank catastrophic failure – 1x10e-5 chance per year

Atmospheric tank 10mm diameter leak – 1x10e-4 chance per year

Pressure vessel catastrophic failure – 1x10e-5 chance per year

Above ground piping full breach failure (pipe size less than 150 mm or 6”) – 1x10e-6 chance per meter per year

Above ground piping full breach failure (pipe size less than 150 mm or 6”) – 1x10e-7 chance per meter per year

External events

There are a number of possible events which could lead to hazardous consequences, such as lightning, flood, hurricane, mudslide impact, plane crash, etc. Since these events are quite unpredictable, there are no generic initiating event frequencies available (Center for Chemical Process Safety, 2015).

Human error initiating events

In general, the likelihood of human error involves a number of factors, such as the frequency of executing a task, whether or not there are written procedures, the degree of stress involved in the task, etc. It is important to understand these various factors so that they can be effectively managed to support high levels of human performance. These factors include:

Having checklists and procedures in place

The level of stress and fatigue experienced by the individual responding to the event

The skill level of the individual responding to the event

The type of task being performed, whether it be a routine, rule-based task versus a knowledge-based task